- Brand Name: Kaisi

- Origin: Mainland China

- is_customized: Yes

- Certification: CE,FCC

- Model Number: SUGON A9

- Soldering iron tip: JBC C210/C245/C115

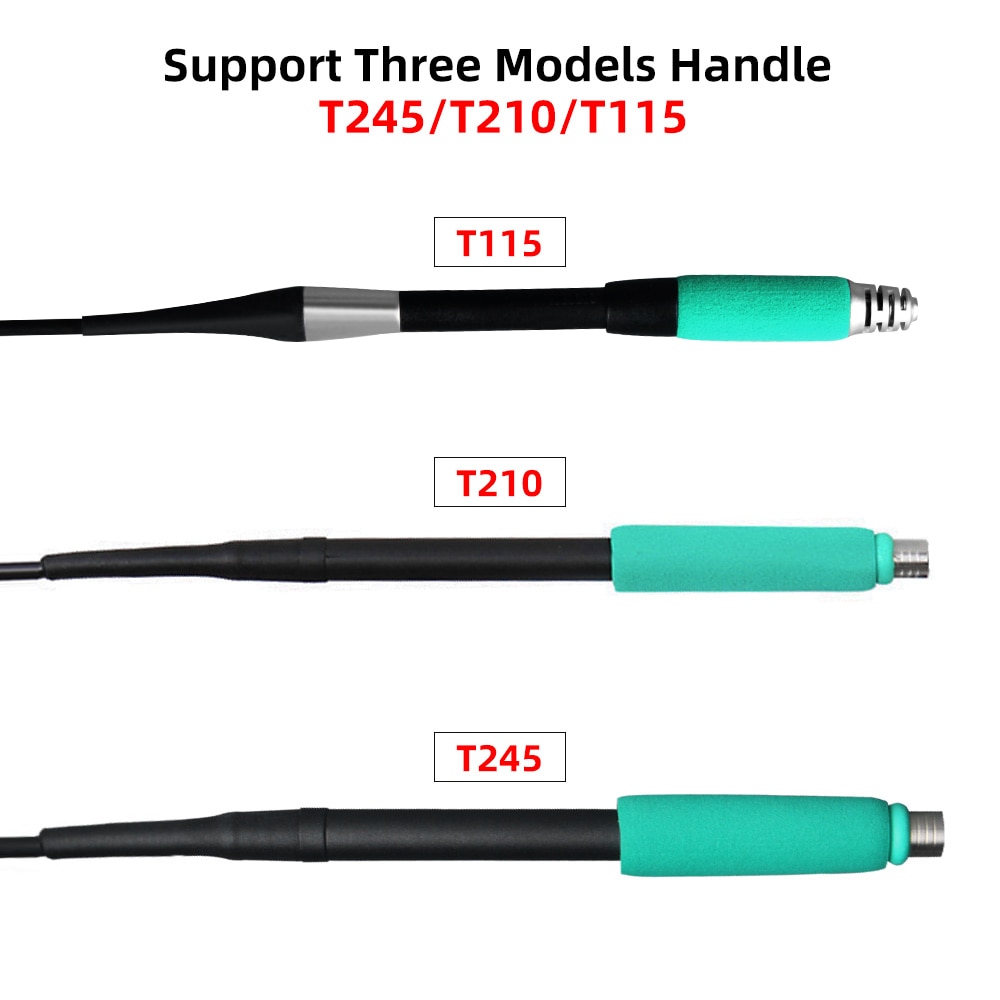

- Handle: T210/T245/T115

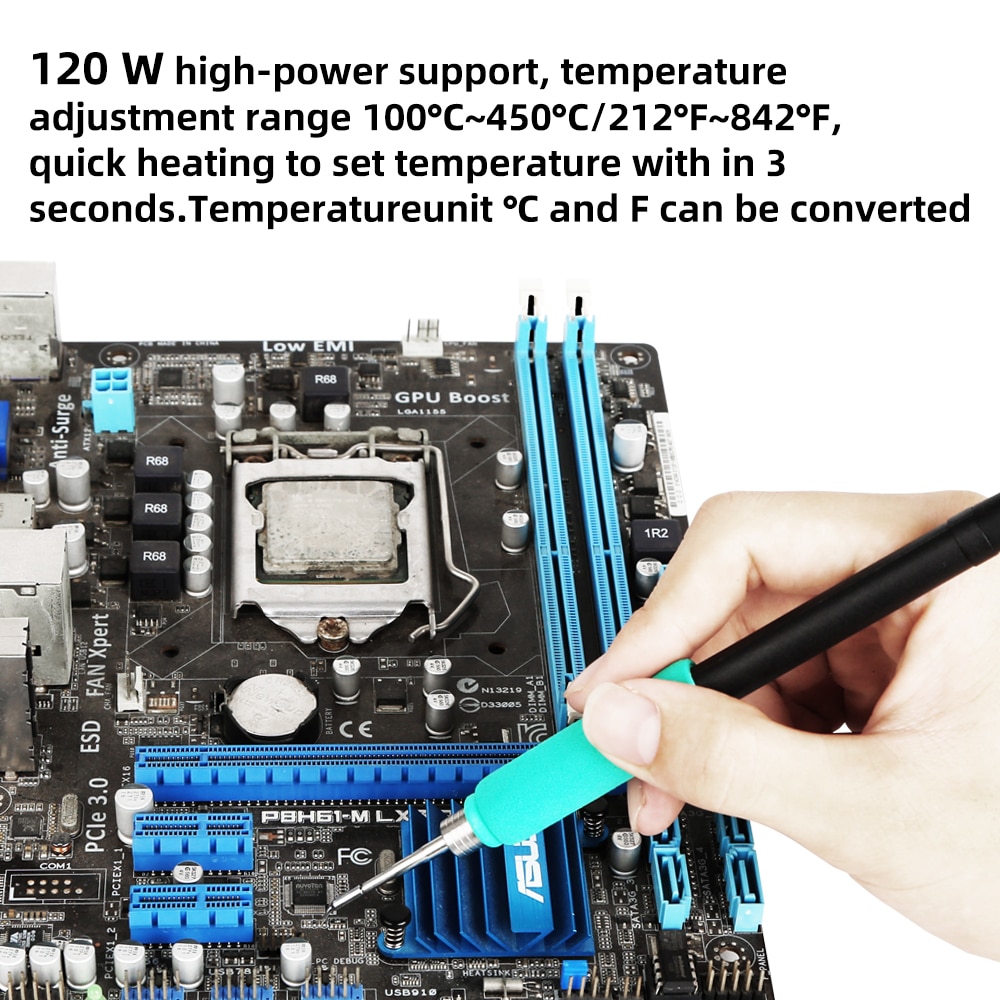

- Power: 120W

SUGON-A9 Soldering Station Compatible JBC Soldering Iron Tips T210/T245/T115 Handle Lead-free Electronic Welding Rework Station

Remind:

To Buy Genuine “SUGON”, Please Look For This Store

Product parameters:

Power: 120W(MAX)

Input voltage: AC220V/AC110V

Frequency: 50-60Hz

Temperature range: 100°C-450°C/212°F-842°F

Product description:

SUGON-A9 is an intelligent soldering station compatible with T115/T210/T245handle,Also compatible with JBC soldering tips,The handle has a dormant metal ring. When the handle is inserted into the stand, it will automatically enter sleep mode. The soldering station is equipped with three soldering iron tips (I, IS, K). The temperature of the soldering station is controlled by the chip program, which is different from the traditional soldering station that uses AC voltage to control the temperature, and the heating speed is fast and accurate.

Tip:

After receiving the A9 soldering station, when using a new soldering iron tip for the first time, insert the new soldering iron tip and heat it for 5 minutes, which can effectively improve the temperature stability of the soldering iron tip.

Notes on handle selection: SUGON A9 is developed based on precision temperature control technology and is the latest generation of soldering stations. The focus of development is: small temperature error (very small error can be achieved through calibration), fast heating, fast temperature recovery, no need for 936 series or DIY, and there is no comparability with other products. Because the 936 series products are only temperature-regulated soldering stations, the temperature difference is very large. If you choose 350 degrees, the actual temperature may be as high as 450 degrees. The diy series is in charge of meeting some people who like high temperature requirements. Beginners, deliberately turn up the temperature. Repair work is no child’s play and cannot be done by feel. Temperature judgment and calibration should be based on a temperature tester. It is recommended to purchase an additional S-191 soldering iron temperature calibrator in the store.

So how to choose the soldering station configuration according to your actual work scope?

1. For processing ultra-fine circuits under the microscope, such as repairing multi-layer circuit boards, complex flying leads, etc., C115 heating core and handle can be selected, the cutter head handles small solder joints, and the pointed tip handles tiny solder joints.

2. Repair mobile phones, car remote controls, precision small electrical appliances, cables, etc., choose C210 heating core and handle, IC socket and other small and medium solder joints, small flying wires and small pointed solder joints.

3. For home appliance maintenance, mobile phone maintenance, and computer motherboards, choose high-power C245 heating cores and handles, large solder joints with cutter heads, and small solder joints with pointed tips. The advantage of C245 is to take into account the solder joint size, high power (120W MAX), However, due to the large size of the soldering iron tip, it is not easy to handle tiny solder joints. To sum up: C115 for small solder joints, C210 for small solder joints, and C245 for large and small solder joints.

Features:

Preset 4 sets of standby temperature (0,150,180,200), “0” is closed, and it can be used when it is lifted.

Software program control, hang up instantly.

Powerful function, with 3 groups of preset memory temperature, short press for one second to read, long press for three seconds to store.

Celsius/Fahrenheit (C/F) conversion

Temperature compensation function,the temperature of the soldering iron tip is automatically compensated during the welding process, so that the soldering iron tip is always kept at the set temperature.

Key lock/open

Buzzer on/off

Intelligent temperature control – through high-end precision PID program, the actual temperature can be monitored and corrected at high speed, fast temperature compensation, and provide the accuracy required by your project.

Reviews

There are no reviews yet.